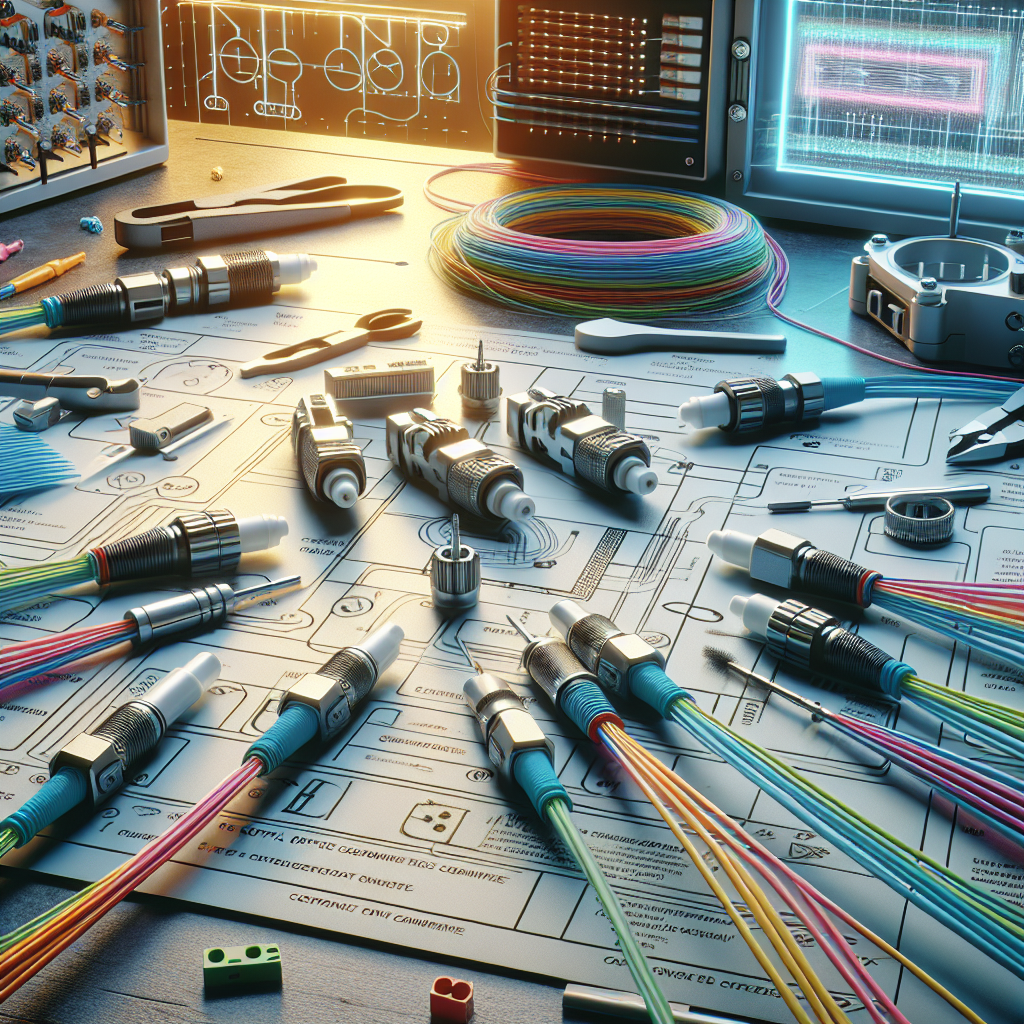

Fiber optic connectors customization is a key process in enhancing connectivity in the world of telecommunications. Companies are constantly looking for ways to optimize their network infrastructure, and customizing fiber optic connectors has proven to be a successful strategy. By tailoring connectors to specific needs, organizations can improve signal quality, reduce downtime, and increase overall efficiency. This innovative approach allows for seamless integration of new technologies, while also ensuring compatibility with existing systems. In this fast-paced digital era, the ability to customize fiber optic connectors is essential for staying ahead of the curve and meeting the demands of modern communication networks.

Understanding Fiber Optic Connectors

Fiber optic technology revolutionized data transmission by using light signals to transfer data through thin, transparent fibers. This innovation allows for faster transmission speeds, higher bandwidth, and increased reliability compared to traditional copper cables. Fiber optic connectors play a crucial role in this process, serving as the interface between optical fibers and various devices to ensure seamless connectivity. These connectors are essential components that determine the efficiency and effectiveness of fiber optic networks.

Overview of Fiber Optic Technology

- Fiber optic technology utilizes glass or plastic fibers to transmit data using light signals.

- The core, cladding, and buffer coating of optical fibers work together to facilitate the transmission of light signals over long distances.

- Fiber optic cables are designed to be lightweight, flexible, and resistant to electromagnetic interference, making them ideal for high-speed data transmission.

Importance of Fiber Optic Connectors in Data Transmission

- Fiber optic connectors enable the connection and disconnection of optical fibers with precision and minimal signal loss.

- Properly installed connectors ensure efficient light signal transmission, reducing the risk of data corruption or loss.

- Customized fiber optic connectors can enhance connectivity by meeting specific network requirements and ensuring compatibility with diverse devices and systems.

Types of Fiber Optic Connectors

- Popular types of fiber optic connectors include LC, SC, ST, and MTP connectors, each with unique features and applications.

- Connector designs vary in size, shape, and mechanism, catering to different installation environments and network configurations.

- Customization options for fiber optic connectors allow for specialized configurations to optimize network performance and meet specific connectivity needs.

Structured Analysis of Fiber Optic Connectors

Understanding Fiber Optic Connectors

Fiber optic connectors are crucial components in ensuring seamless connectivity within network systems. A structured analysis of fiber optic connectors involves delving into the intricate details of their design, functionality, and the pivotal role they play in facilitating high-speed data transmission. Below are the key elements that constitute a structured analysis of fiber optic connectors:

- Components of a Fiber Optic Connector

A fiber optic connector is typically composed of several essential parts, each serving a specific function to maintain the integrity of the optical signal transmission. These components include the ferrule, which holds the fiber in place, the connector body, the coupling mechanism, and the boot that protects the connection point from dust and damage. The precision and quality of these components significantly impact the overall performance and reliability of the connector.

- Functionality of Fiber Optic Connectors in Network Systems

Fiber optic connectors act as the bridge between optical fibers, enabling the seamless transmission of data signals across network systems. Their primary function is to align and join individual fibers to facilitate efficient light transmission between them. By ensuring proper alignment and minimizing signal loss, connectors play a critical role in maintaining signal integrity and maximizing the efficiency of data transfer within the network.

- Impact of Connector Quality on Transmission Speed

The quality of fiber optic connectors directly influences the transmission speed and overall performance of network systems. High-quality connectors with precise alignment and low insertion loss contribute to faster data transmission rates and enhanced signal reliability. Conversely, poor-quality connectors or those with alignment issues can lead to signal degradation, increased latency, and potential data loss. Therefore, investing in high-quality, customized fiber optic connectors is essential for optimizing connectivity and maximizing the efficiency of network operations.

Customization Options for Fiber Optic Connectors

Advantages of Customizing Fiber Optic Connectors

Fiber optic connectors play a crucial role in ensuring seamless connectivity within networks. Customizing these connectors offers a myriad of advantages that can significantly enhance network performance and reliability:

-

Optimized Performance: Customizing fiber optic connectors allows for the tailoring of components to specific network requirements, resulting in optimized performance. This ensures that the connectors meet the exact needs of the network, leading to enhanced efficiency and reliability.

-

Improved Signal Quality: By customizing fiber optic connectors, it is possible to improve signal quality within the network. This can help in reducing signal loss and interference, leading to clearer and more stable communication transmissions.

-

Enhanced Durability: Customization options often include the use of high-quality materials and advanced manufacturing techniques, resulting in connectors that are more durable and long-lasting. This increased durability can help in reducing maintenance costs and downtime associated with connector failure.

-

Compatibility: Customizing fiber optic connectors allows for ensuring compatibility with specific network components and configurations. This can be particularly beneficial in complex network setups where standard connectors may not provide the required compatibility.

Tailoring Connectors to Specific Network Requirements

Customization of fiber optic connectors involves tailoring the connectors to meet specific network requirements. This can include:

-

Connector Type: Customization options allow for selecting the most suitable connector type based on factors such as network architecture, transmission speed, and environmental conditions. Common connector types include LC, SC, ST, and MTP/MPO.

-

Fiber Mode: Customizing connectors involves choosing the appropriate fiber mode, such as single-mode or multi-mode, based on the distance and bandwidth requirements of the network. This ensures optimal signal transmission and performance.

-

Polish Type: Customization extends to selecting the polish type of the connectors, including UPC (Ultra Physical Contact) or APC (Angled Physical Contact). The choice of polish type can impact signal loss and reflection levels in the network.

-

Cable Compatibility: Customizing fiber optic connectors also involves ensuring compatibility with the specific cable types used in the network. This includes considerations such as cable diameter, jacket material, and connector interface.

Customization Process and Considerations

The customization process for fiber optic connectors typically involves the following steps and considerations:

-

Consultation: Engaging with experienced professionals or manufacturers to discuss network requirements and customization options is essential in determining the most suitable connectors for the network.

-

Design: Customization often involves designing connectors with specific features and specifications tailored to the network’s needs. This may include selecting materials, connector configurations, and performance parameters.

-

Testing: Rigorous testing of customized connectors is crucial to ensure compliance with industry standards and optimal performance. Testing may involve various parameters such as insertion loss, return loss, and durability under different environmental conditions.

-

Quality Assurance: Customized fiber optic connectors should undergo quality assurance processes to guarantee reliability and performance. This may include inspections, certifications, and compliance with industry regulations.

-

Installation and Maintenance: Proper installation and regular maintenance of customized connectors are essential to maximize their performance and longevity. Following manufacturer guidelines and best practices can help in ensuring optimal connectivity within the network.

Benefits of Custom Fiber Optic Connectors

Custom fiber optic connectors offer a range of benefits that can significantly enhance connectivity and overall performance in various applications. These benefits include:

-

Improved Signal Quality and Reliability: By customizing fiber optic connectors to specific requirements, signal quality can be optimized, leading to reduced signal loss and improved overall reliability of the connection. This is crucial in high-speed data transmission applications where signal integrity is paramount.

-

Enhanced Data Transmission Speeds: Custom fiber optic connectors can be tailored to minimize signal interference, resulting in enhanced data transmission speeds. This is particularly important in environments where high bandwidth and fast data transfer rates are essential, such as data centers and telecommunications networks.

– Optimized Performance in Challenging Environments: Custom fiber optic connectors can be designed to withstand harsh environmental conditions, such as extreme temperatures, moisture, and vibrations. By selecting the appropriate materials and configurations, custom connectors can ensure reliable performance even in challenging operating environments, making them ideal for industrial and outdoor applications.

Advanced Technologies in Fiber Optic Connector Customization

Innovations in Connector Design for Specialized Applications:

– Miniaturization: Custom fiber optic connectors are now being designed to be smaller and more compact, catering to applications where space is limited.

– High Density: With the increasing demand for data transmission capacity, custom connectors are being developed to accommodate higher numbers of fiber connections within a limited space.

– Robustness: Custom connectors are now being engineered to withstand harsh environmental conditions, ensuring reliable connectivity in challenging settings such as industrial facilities or outdoor installations.

– Multi-fiber: Innovations in multi-fiber connectors allow for the simultaneous transmission of multiple data streams, enhancing efficiency and performance in data-intensive applications.

Integration of Smart Features in Custom Connectors:

– Remote Monitoring: Custom fiber optic connectors with built-in sensors enable real-time monitoring of connection status and performance, facilitating proactive maintenance and troubleshooting.

– Self-cleaning Mechanisms: Advanced custom connectors incorporate self-cleaning features to ensure optimal performance by preventing dust and debris accumulation, reducing maintenance requirements.

– Bi-directional Communication: Custom connectors with bi-directional communication capabilities enable intelligent data exchange between connected devices, enhancing overall network efficiency and reliability.

Future Trends in Fiber Optic Connector Customization:

– Optical Signal Processing: Custom connectors are expected to integrate optical signal processing technologies for on-the-fly data manipulation, enabling faster data transmission speeds and reduced latency.

– Enhanced Security Features: Future custom connectors may incorporate advanced encryption and authentication mechanisms to ensure secure data transmission, addressing the growing concerns around data privacy and cybersecurity.

– Compatibility with Emerging Technologies: Custom connectors will need to be adaptable to accommodate the requirements of emerging technologies such as 5G networks, Internet of Things (IoT) devices, and artificial intelligence applications, driving the need for flexible and future-proof connector designs.

Case Studies: Customization Success Stories

Customizing fiber optic connectors has proven to be a pivotal strategy in enhancing connectivity for various industries. Here are some compelling success stories showcasing the positive outcomes and performance enhancements achieved through custom connector solutions:

- Healthcare Sector Transformation

-

A leading hospital network implemented custom fiber optic connectors with enhanced durability and flexibility to support their high-speed data transmission requirements for medical imaging systems. This customization significantly reduced signal loss and improved overall system reliability, ensuring seamless connectivity crucial for patient care.

-

Telecommunication Network Optimization

-

A telecommunications company sought to upgrade its network infrastructure to accommodate increasing data demands. By customizing fiber optic connectors with specific angle-polished ferrules and low insertion loss characteristics, they achieved a substantial improvement in signal quality and transmission efficiency. This customization enabled the company to deliver faster and more reliable communication services to its customers.

-

Aerospace Industry Innovation

- In the aerospace sector, a leading manufacturer customized fiber optic connectors for use in avionics systems. By designing connectors with enhanced shock and vibration resistance, as well as reduced size and weight, they successfully optimized data transmission performance in harsh aerospace environments. This customization not only improved connectivity within the aircraft but also contributed to overall weight reduction, enhancing fuel efficiency.

These case studies demonstrate the tangible benefits of customizing fiber optic connectors to meet specific industry requirements. By tailoring connector solutions to address unique connectivity challenges, organizations can achieve superior performance, reliability, and efficiency in their data transmission systems.

Best Practices for Implementing Custom Fiber Optic Connectors

Collaboration with Experienced Manufacturers

- In the process of customizing fiber optic connectors, it is crucial to collaborate with manufacturers who have a proven track record in producing high-quality connectors.

- Experienced manufacturers possess the technical expertise and resources necessary to understand the specific requirements of custom connectors and ensure they meet industry standards.

- By partnering with reputable manufacturers, companies can leverage their knowledge to design connectors that are tailored to the unique needs of their network infrastructure.

Testing and Quality Assurance Protocols

- Implementing rigorous testing and quality assurance protocols is essential when customizing fiber optic connectors to guarantee optimal performance and reliability.

- Conducting thorough testing procedures ensures that custom connectors meet the required specifications and standards for connectivity and signal transmission.

- Quality assurance protocols help identify any potential issues or defects in the customized connectors before they are deployed in the network, reducing the risk of downtime or connectivity issues.

Maintenance and Upkeep of Customized Connectors

- Regular maintenance and upkeep of customized fiber optic connectors are critical to ensuring long-term connectivity and performance.

- Establishing a maintenance schedule that includes cleaning, inspection, and testing of custom connectors can help prevent signal loss and connectivity issues over time.

- By proactively maintaining customized connectors, companies can extend their lifespan and minimize the need for costly repairs or replacements, ultimately enhancing overall network connectivity.

Troubleshooting and Common Challenges

When dealing with custom fiber optic connectors, it is crucial to be aware of potential troubleshooting issues and common challenges that may arise during implementation. Proper troubleshooting techniques can help identify and resolve connectivity problems efficiently, ensuring the seamless operation of customized fiber optic systems.

Identifying Issues with Custom Connectors

-

Alignment Problems: Customized connectors may face alignment issues due to variations in design or manufacturing processes. Misalignment can lead to signal loss and poor connectivity.

-

Compatibility Concerns: Custom connectors may not always be compatible with standard components, resulting in connection difficulties and signal disruptions.

-

Contamination: Dust, dirt, or debris can accumulate on custom connectors, affecting signal transmission and causing connectivity issues.

Solutions for Connectivity Problems

-

Regular Inspection: Conducting routine inspections of custom connectors can help detect alignment issues or contamination early on, allowing for timely maintenance or cleaning.

-

Cleaning Procedures: Implementing proper cleaning procedures using specialized tools and solutions can help remove contaminants and improve connectivity.

-

Alignment Adjustment: In cases of misalignment, adjusting the custom connectors using precision tools can realign the fibers and restore optimal connectivity.

Ensuring Longevity and Durability of Customized Fiber Optic Connectors

-

Proper Handling: Ensuring proper handling practices during installation and maintenance can prevent damage to custom connectors and extend their lifespan.

-

Quality Materials: Using high-quality materials in the customization of fiber optic connectors can enhance durability and resistance to wear and tear.

-

Regular Testing: Conducting regular testing of custom connectors for performance and signal quality can help identify potential issues early and ensure long-term reliability.

FAQs: Fiber Optic Connectors Customization: Enhancing Connectivity

What is fiber optic connectors customization?

Fiber optic connectors customization involves tailoring connectors to meet specific requirements such as different fiber types, cable sizes, and connection interfaces. This ensures optimal performance, reliability, and compatibility for specific applications.

Why is customization important for fiber optic connectors?

Customization of fiber optic connectors allows for improved connectivity, reduced insertion loss, increased transmission efficiency, and enhanced signal quality. It also enables flexibility in network design and installation, making it easier to adapt to evolving technology requirements.

What are some common customization options for fiber optic connectors?

Some common customization options for fiber optic connectors include choosing the connector type (such as SC, LC, or ST), selecting the fiber type (single-mode or multi-mode), specifying the cable diameter and length, and choosing the polishing type (UPC or APC) for optimal performance.

How does fiber optic connectors customization benefit network performance?

Customized fiber optic connectors ensure a secure and reliable connection, minimizing signal loss and interference. This leads to improved data transmission speed, greater bandwidth capacity, and enhanced overall network performance, making it ideal for high-speed data transfer and long-distance communication applications.