Fiber optic connectors play a crucial role in the seamless transmission of data and communication in today’s fast-paced digital world. However, ensuring compatibility between different connectors is vital to guaranteeing optimal performance and reliability. This intricate process involves rigorous testing to ensure that connectors from various manufacturers can seamlessly work together without compromising data integrity. In this article, we delve into the nuances of fiber optic connectors compatibility testing and explore its significance in maintaining smooth and uninterrupted communication networks. Join us as we uncover the importance of compatibility testing in the ever-evolving landscape of fiber optic technology.

Compatibility testing is crucial when exploring the intricacies of fiber optic connectors. Ensuring that connectors are compatible with each other and with any equipment they will be connected to is essential for the seamless functioning of the network. Without proper compatibility testing, there is a risk of signal loss, poor performance, and even damage to the connectors themselves. Overall, compatibility testing plays a vital role in maintaining the reliability and efficiency of fiber optic connections.

Understanding Fiber Optic Connectors

Fiber optic connectors serve as crucial components in the realm of fiber optic technology, facilitating the seamless transmission of data through optical fibers. These connectors are meticulously engineered to ensure precise alignment of optical fibers, enabling efficient and reliable data transfer. The intricate design of fiber optic connectors plays a pivotal role in maintaining signal integrity and minimizing data loss.

Overview of Fiber Optic Connectors

- Fiber optic connectors are mechanical devices used to join fiber optic cables seamlessly.

- These connectors feature precision components such as ferrules, sleeves, and housing to ensure accurate alignment of fibers.

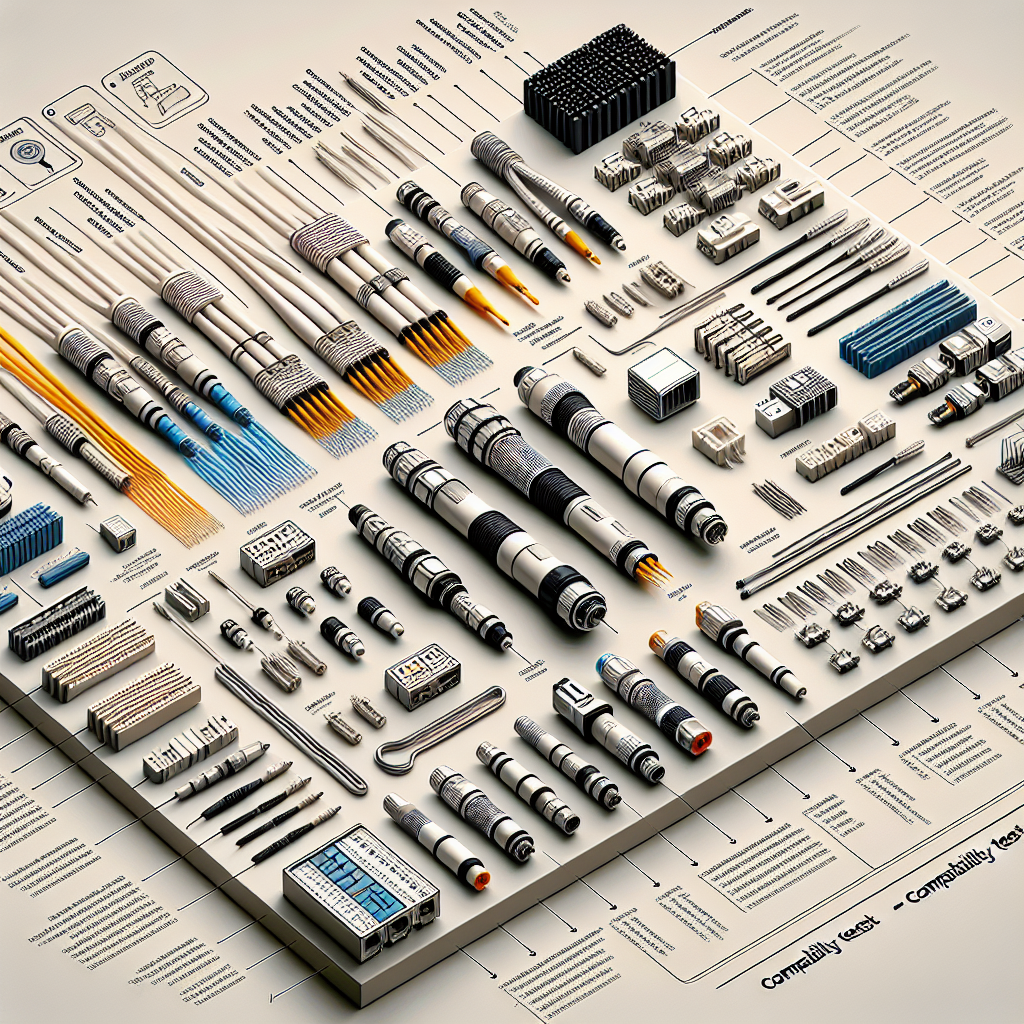

- Various types of fiber optic connectors exist, each designed for specific applications and environments.

Importance of Connectors in Fiber Optic Technology

- Connectors act as the interface between optical fibers and enable connectivity between different network components.

- Properly selected and installed connectors are essential for achieving optimal performance in fiber optic systems.

- Compatibility testing of connectors is crucial to ensure seamless integration within the network infrastructure.

Types of Fiber Optic Connectors

Single-mode Connectors

Single-mode connectors are designed for use with single-mode fiber optic cables, which have a smaller core size compared to multimode fibers. These connectors are commonly used in long-distance communication systems due to their ability to transmit signals over greater distances with lower attenuation. Single-mode connectors offer higher bandwidth and reliability, making them ideal for applications requiring high data transfer rates and precision.

Characteristics and Usage

- Single-mode connectors have a core size of 8-10 microns, allowing for the transmission of a single mode of light.

- These connectors are more expensive than multimode connectors but offer superior performance in terms of signal quality and distance.

- Single-mode connectors are typically used in telecommunications networks, internet infrastructure, and long-haul data transmission systems.

- The narrow core size of single-mode fibers enables the transmission of signals over longer distances without significant loss or interference.

Common Single-mode Connectors

- LC Connector:

- The LC connector is a small form factor connector widely used in high-density applications.

-

It features a 1.25mm ceramic ferrule and offers reliable performance for single-mode fiber connections.

-

SC Connector:

- The SC connector is a popular choice for single-mode fiber installations in data centers and telecom networks.

-

It has a push-pull locking mechanism for secure connections and is easy to install.

-

FC Connector:

- The FC connector is often used in laboratory and test environments for high precision single-mode connections.

- It features a threaded coupling mechanism for stable and reliable connections.

Multi-mode Connectors

Multi-mode fiber optic connectors are designed to work with larger core sizes, typically around 50 to 62.5 microns. These connectors are suitable for shorter distance transmissions due to their higher dispersion and attenuation compared to single-mode connectors. Understanding the characteristics and usage of multi-mode connectors is crucial for ensuring effective communication systems.

- Characteristics and Usage

- Multi-mode connectors are commonly used in local area networks (LANs), data centers, and other short-distance communication applications.

- They are cost-effective solutions for transmitting data over shorter distances, making them ideal for high-speed networking within confined spaces.

-

These connectors are compatible with light sources such as LED (Light Emitting Diode) and VCSEL (Vertical-Cavity Surface-Emitting Laser) for efficient data transmission.

-

Common Multi-mode Connectors

- ST Connector: This is a popular bayonet-style connector that is easy to install and remove. It is commonly used in Ethernet networks and offers good performance for multi-mode fiber optic connections.

- SC Connector: The SC connector features a push-pull coupling mechanism and is widely used in data communication networks. It provides low insertion loss and high repeatability for multi-mode fiber connections.

- LC Connector: Known for its small form factor, the LC connector is suitable for high-density installations and is commonly used in switches, routers, and other networking equipment. It offers reliable performance for multi-mode fiber optic links.

Understanding the unique characteristics and applications of multi-mode fiber optic connectors is essential for effectively integrating them into communication systems. Compatibility testing plays a crucial role in ensuring seamless connectivity and optimal performance when utilizing multi-mode connectors in network infrastructure.

Importance of Compatibility Testing

Ensuring Seamless Data Transmission

- Impact of Incompatible Connectors

Incompatible fiber optic connectors can result in signal loss, data corruption, and overall network performance degradation. When connectors do not align properly or have different core sizes, it can lead to signal attenuation and reflection, causing a decrease in the quality of data transmission. This can result in latency issues, dropped connections, and reduced bandwidth, ultimately affecting the efficiency and reliability of the network.

- Need for Compatibility Testing

Compatibility testing is crucial to ensure that fiber optic connectors work seamlessly together within a network infrastructure. By conducting compatibility testing, network administrators can verify that connectors from different manufacturers or with varying specifications can effectively communicate without causing signal loss or performance issues. This process helps identify potential compatibility issues before deployment, reducing the risk of network downtime and data loss. Ultimately, compatibility testing plays a vital role in maintaining the integrity of data transmission across fiber optic networks.

Factors Affecting Compatibility

Physical Compatibility

- Physical compatibility in fiber optic connectors refers to the ability of connectors from different manufacturers to physically fit together and make a secure connection.

- Factors such as connector size, shape, and alignment are crucial in ensuring physical compatibility.

- Even slight variations in physical dimensions can lead to difficulties in mating connectors, resulting in signal loss or poor performance.

- Compatibility testing helps in identifying and addressing physical compatibility issues before deployment, ensuring smooth connectivity and optimal performance.

Optical Compatibility

- Optical compatibility is another critical aspect to consider when dealing with fiber optic connectors.

- It involves ensuring that the optical characteristics of the connectors, such as core size, numerical aperture, and alignment, are well-matched.

- Mismatched optical properties can lead to signal attenuation, reflections, or dispersion, affecting the overall signal quality.

- Compatibility testing plays a vital role in verifying the optical compatibility of connectors, helping in achieving efficient light transmission and minimizing signal loss.

Methods of Fiber Optic Connectors Compatibility Testing

Visual Inspection

Visual inspection is a crucial step in fiber optic connectors compatibility testing as it allows for the identification of any visible defects or irregularities that may impact performance. This process involves a detailed examination of the connector components to ensure proper alignment and cleanliness, which are essential for optimal signal transmission.

Importance of Visual Inspection

– Visual inspection helps in detecting any physical damage such as scratches, cracks, or contamination on the connectors that could affect their functionality.

– It ensures that the connectors are properly aligned and that there are no gaps or misalignments that could lead to signal loss.

– By conducting a visual inspection, technicians can verify that the connectors match in terms of connector type, polish type, and ferrule size, which is vital for compatibility.

Steps in Visual Inspection

1. Begin by examining the connector end faces under a fiber optic microscope to check for any signs of damage or contamination.

2. Inspect the ferrules for any scratches, pits, or chips that could impact signal quality.

3. Verify that the connectors are properly aligned and that there are no gaps between the mating surfaces.

4. Clean the connector end faces using appropriate tools and techniques to ensure optimal performance.

5. Document any findings and take necessary corrective actions if issues are identified during the visual inspection process.

Visual inspection is a fundamental aspect of fiber optic connectors compatibility testing, as it allows for the early detection of potential issues that could compromise the integrity of the optical connection. By following a structured visual inspection process, technicians can ensure that the connectors meet the required standards for compatibility and performance.

Insertion Loss Testing

Understanding Insertion Loss

Insertion loss in fiber optic connectors refers to the amount of optical power lost when light passes through the connector. It is a critical parameter that directly impacts the performance and efficiency of the fiber optic connection. The lower the insertion loss, the better the quality of the connection, as it indicates minimal signal attenuation.

In fiber optic communication systems, insertion loss is a key consideration as it can affect the overall transmission quality and signal strength. High insertion loss can lead to decreased data transmission rates, signal degradation, and reduced system reliability. Therefore, accurate measurement and management of insertion loss are essential in ensuring optimal network performance.

Procedure for Insertion Loss Testing

-

Equipment Setup: To conduct insertion loss testing, specialized equipment such as a light source, power meter, and optical time-domain reflectometer (OTDR) may be required. Ensure that the testing environment is free from any potential sources of interference that could impact the accuracy of the measurements.

-

Connector Preparation: Before testing, inspect the connectors for any damage or contamination that could affect the insertion loss readings. Clean the connectors using appropriate tools and techniques to ensure optimal performance during testing.

-

Connection Establishment: Connect the light source to one end of the fiber optic link and the power meter to the other end. Ensure that the connectors are securely attached to minimize any additional loss due to poor alignment or loose connections.

-

Measurement: Activate the light source to emit a stable optical signal through the fiber optic link. The power meter will measure the received signal strength, allowing for the calculation of insertion loss. Repeat the measurements multiple times to ensure accuracy and consistency.

-

Analysis and Documentation: Once the insertion loss measurements are complete, analyze the data to determine the overall performance of the fiber optic connection. Record the results along with relevant details such as connector types, cable lengths, and testing conditions for future reference and comparison.

-

Interpretation: Compare the measured insertion loss values against industry standards and specifications to evaluate the quality of the fiber optic connection. Identify any discrepancies or deviations that may indicate potential issues requiring further investigation or corrective action.

Return Loss Testing

Return loss testing is a critical method in assessing the performance of fiber optic connectors to ensure optimal compatibility. This testing is particularly important in maintaining signal integrity and minimizing signal loss in fiber optic systems.

Significance of Return Loss:

– Return loss measures the amount of light that is reflected back from the connection point in a fiber optic system.

– A high return loss indicates poor connection quality, resulting in increased signal loss and potential disruptions in data transmission.

– Maintaining low return loss levels is essential for achieving efficient and reliable communication through fiber optic networks.

Conducting Return Loss Testing:

– Return loss testing involves using specialized equipment to measure the amount of light reflected back from the connector interface.

– By comparing the intensity of the transmitted light with the reflected light, technicians can calculate the return loss value.

– Testing is typically performed at various wavelengths to ensure consistent performance across different operating conditions.

– Results from return loss testing provide valuable insights into the quality of the connector termination and help identify any issues that may impact system performance.

Challenges in Compatibility Testing

Environmental Factors

-

Influence of Temperature and Humidity

Fiber optic connectors are highly sensitive to environmental conditions, with temperature and humidity being primary factors that can affect their performance. Fluctuations in temperature can cause the connectors to expand or contract, potentially leading to misalignments or signal loss. High humidity levels can also result in moisture accumulation within the connectors, causing signal degradation and even corrosion over time. It is imperative to conduct compatibility testing under varying temperature and humidity settings to ensure that the connectors can withstand real-world environmental challenges. -

Mitigating Environmental Challenges

To address the impact of environmental factors on fiber optic connectors, compatibility testing plays a crucial role in assessing the resilience of the connectors under different conditions. By subjecting the connectors to extreme temperatures and varying humidity levels during testing, manufacturers can identify potential vulnerabilities and implement design modifications to enhance durability. Additionally, protective measures such as using specialized coatings or sealing techniques can help mitigate the effects of temperature and humidity on connector performance. Compatibility testing serves as a vital tool in ensuring that fiber optic connectors meet the stringent requirements for reliable and consistent operation in diverse environmental settings.

Upcoming Technologies and Compatibility

In the rapidly evolving landscape of fiber optic technology, staying ahead of upcoming technologies is crucial for ensuring seamless compatibility across networks. As next-generation networks continue to emerge, the need for robust compatibility testing becomes increasingly paramount. Here are some key considerations for addressing upcoming technologies and compatibility:

- Considerations for Next-Generation Networks

- With the advent of technologies such as 5G, IoT, and cloud computing, the demands on fiber optic networks are expanding exponentially. Compatibility testing must take into account the specific requirements of these advanced technologies to ensure optimal performance and reliability.

-

Next-generation networks often involve higher data transfer speeds, increased bandwidth requirements, and more complex network architectures. Compatibility testing must assess how fiber optic connectors interact with these advancements to maintain seamless connectivity.

-

Ensuring Future Compatibility

- Anticipating the future trajectory of fiber optic technology is essential for ensuring long-term compatibility. Compatibility testing should not only focus on current standards but also consider potential advancements on the horizon.

- Future compatibility encompasses not only technological advancements but also industry standards and regulations. Ensuring that fiber optic connectors are compatible with upcoming standards can help avoid costly upgrades and disruptions in the future.

FAQs

What is fiber optic connectors compatibility testing?

Fiber optic connectors compatibility testing is the process of ensuring that different types of fiber optic connectors can properly connect and communicate with each other. This testing is crucial in the world of fiber optic technology, as it ensures that there are no issues with data transmission speed, quality, or compatibility when connectors from different manufacturers or standards are used together.

Why is compatibility testing important for fiber optic connectors?

Compatibility testing is important for fiber optic connectors because it guarantees seamless communication between different systems and components in a fiber optic network. It helps avoid any potential issues such as signal loss, data corruption, or connection failure that may arise from using incompatible connectors. This testing also ensures that the network will operate efficiently and effectively, without any disruptions or downtime.

How is fiber optic connectors compatibility testing conducted?

Fiber optic connectors compatibility testing is typically conducted by connecting connectors from different manufacturers or standards and testing their performance using specialized equipment. This may involve measuring insertion loss, return loss, and reflection levels as well as checking for any physical or mechanical mismatches between the connectors. The results of the testing help determine whether the connectors are compatible and can reliably transmit data without any issues.

What are the potential risks of not performing compatibility testing for fiber optic connectors?

The potential risks of not performing compatibility testing for fiber optic connectors include poor signal quality, data transmission errors, connection failures, and network downtime. Using incompatible connectors can lead to performance issues and system failures that can be costly and disruptive to businesses. It is crucial to conduct compatibility testing to ensure that all connectors in a fiber optic network are compatible and reliable for seamless communication.